Outsourced Warehousing And Fulfillment Fundamentals Explained

Wiki Article

The Greatest Guide To Outsourced Warehousing And Fulfillment

Table of ContentsSome Ideas on Outsourced Warehousing And Fulfillment You Need To KnowAll about Outsourced Warehousing And FulfillmentSee This Report on Outsourced Warehousing And FulfillmentOutsourced Warehousing And Fulfillment Fundamentals ExplainedOutsourced Warehousing And Fulfillment Can Be Fun For AnyoneNot known Details About Outsourced Warehousing And Fulfillment

As even more companies outsource their warehousing, they'll require to make certain they're picking the right companion to ensure the greatest level of solution. It's much easier to take the following action in your endeavor currently that you have a company understanding of warehousing. Having the ability to identify the right storage facility solutions and appropriate partnerships can take some time; don't rush on your own.Warehousing is the process of saving as well as delivering physical goods in a warehouse. Storage facilities can be utilized in different service settings for saving goods prior to delivering them to a specific area or various consumers. A business like Walmart might make use of a warehouse to keep its goods in mass and deliver them to its stores when supply falls short, and also items are required to be put on racks.

You could have discovered terms storehouse and also distribution facility are made use of interchangeably. A storage facility is just a building that is utilized to keep stock.

Unknown Facts About Outsourced Warehousing And Fulfillment

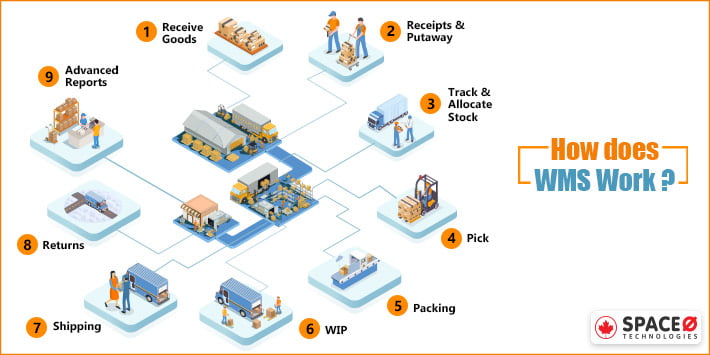

A product that comes and also goes in and also out of a storehouse goes through numerous procedures. The inbound process is receiving and keeping goods from a provider to a storage facility or a fulfillment.

These are as adheres to: After the trailer is anchored at the stockroom, workers inspect the stock to make sure that all things that were expected exist and also are not harmed. Then the inventory is assigned License Plate Numbers (LPNs) as well as considered putaway. After the stock is inspected in the receiving procedure, it is required to storage space where it is kept.

Some discount store products with each other based on the product kind or called for storage temperature etc. to optimize storage space locations to optimize area usage. The outbound Refine is the picking, packaging, as well as delivery of products from the warehouse to a client or end individual. The outbound procedure is further divided into the following processes - outsourced warehousing and fulfillment.

Outsourced Warehousing And Fulfillment Things To Know Before You Buy

Selecting is the process of gathering all the items in order from their corresponding storage locations and transferring them to a staging area. As soon as all things in an order are selected and brought to a staging location, the following action is to get them prepared to be shipped to the customer or end customer.

The last action in completing an order after it has been selected as well as packed is to choose a suitable service provider, load the order on the provider and also ship it to the client's delivery address. All the above actions and processes entailed with warehousing can conveniently be taken care of and kept track of making use of a Warehouse Management System.

A warehouse management system (WMS) contains software application and also processes that allow companies to control and also administer stockroom operations from the moment items or products enter a stockroom until they vacate. Warehouses rest at the facility of manufacturing and supply chain procedures due to the fact that they hold every one of the material used or created in those procedures, from resources to end up items. outsourced warehousing and fulfillment.

What Does Outsourced Warehousing And Fulfillment Mean?

If raw materials are not obtained appropriately or parts are lost in a stockroom, the supply chain may be slowed or interfered with. WMSes are crucial in guaranteeing that these procedures function smoothly by tracking supply as well as making certain that items are stored and also arranged appropriately, as well as delivered and also tracked precisely.Number 1. Each of the 3 main SCM systems has a certain duty in handling orders and also sharing data with the various other 2. The WMS takes care of the information as well as procedures relating to the motion of goods via a warehouse. Figure 1 shows each system's function in handling orders and also the kinds of information they require to share with each various other to guarantee that the ideal item reaches the client promptly.

Its duty in inventory is to track the supply data that can be found in from barcode readers as well as radio frequency identification (RFID) tags and also update the stock administration module in the ERP system to ensure it has the current info. An integration link integrates the stock information that is saved in the ERP system and also the WMS.

10 Simple Techniques For Outsourced Warehousing And Fulfillment

It is essentially a database of comprehensive details concerning delivery carriers however is also a transactional and interaction system for planning, carrying out as well this page as tracking the deliveries. Sometimes a TMS will be integrated with the WMS to enable better sychronisation of the inbound and also outgoing logistics jobs that happen at the interface of warehouses and also products shippers, such as palletization of goods, labor organizing, backyard management, lots building as well as cross-docking., including area selecting, wave selecting and also batch selecting. Storehouse employees can likewise utilize great deal zoning and also task interleaving features to direct the pick-and-pack jobs in the most efficient way., which makes it possible for the WMS to send bills of lading (B/L) ahead of the shipment, generate packing listings as well as billings for the shipment as well as send breakthrough delivery notifications to recipients.

The primary attribute of a cloud-based WMS versus the traditional on-premises system is that the software is organized and also taken care of by the WMS vendor or a cloud company. This takes the concern of setting up, handling and also upgrading the system off the organization's find out IT department. Due to the fact that they are much easier to set up as well as much less costly to manage, internet cloud-based WMSes have a tendency to be preferred by SMBs.

Outsourced Warehousing And Fulfillment Fundamentals Explained

Pros of cloud-based WMS consist of the following: Faster application. Conventional on-premises WMSes can normally take months to execute, whereas cloud-based WMS deployments can be finished in weeks, depending upon the complexity. This indicates that organizations have a faster course to a favorable ROI and can capitalize on the cloud WMS capabilities faster, which is a significant advantage in the busy contemporary economic climate.Report this wiki page